Unlock The Power Of CT Iron: A Comprehensive Guide

CT Iron represents a cornerstone in modern metallurgy, offering a blend of strength, versatility, and efficiency that makes it indispensable in countless industries. Whether you're exploring its historical significance or its cutting-edge applications, understanding this remarkable material opens doors to innovation and progress.

As we delve into the world of CT Iron, we'll uncover its properties, production methods, and applications that have shaped modern manufacturing. This guide aims to equip you with the knowledge to appreciate its importance and make informed decisions when working with this versatile material.

Table of Contents

- The Rich History of CT Iron

- Composition and Properties of CT Iron

- Manufacturing Process

- Types of CT Iron

- Applications in Various Industries

- Advantages and Disadvantages

- Maintenance and Care

- The Future of CT Iron

The Rich History of CT Iron

Connecticut has a storied past in the iron industry, marked by innovation and craftsmanship. The state's northwest corner, with its lush forests and abundant natural resources, became the heart of iron production during the 18th and 19th centuries. The Connecticut Iron Trail, stretching 4.1 miles through Housatonic State Forest and Canaan Mountain Natural Area Preserve, stands as a testament to this legacy. Here, remnants of furnaces and forges serve as a reminder of the state's industrial roots.

The British Iron Association of Connecticut, established to unite enthusiasts of British motorcycles, highlights the community's passion for engineering excellence. This association fosters the exchange of knowledge on all facets of British motorcycling, paralleling the state's historic dedication to iron and metalworking.

Composition and Properties of CT Iron

Key Components

Cast iron, an alloy primarily composed of iron (Fe), carbon (C), and silicon (Si), forms the basis of CT Iron. It typically contains 2 to 4 percent carbon, along with varying amounts of silicon and manganese, and traces of impurities like sulfur and phosphorus. These elements influence the material's mechanical properties:

- Carbon: Determines the form in which carbon appears, affecting hardness and ductility.

- Silicon: Enhances wear resistance and machinability.

- Manganese: Improves strength and toughness.

Notable Properties

One of CT Iron's most significant advantages is its relatively low melting temperature, making it ideal for casting complex shapes. Its machinability, light weight, strength, and wear resistance further enhance its appeal. Additionally, its damping capabilities make it a preferred choice for vibration-sensitive applications.

Manufacturing Process

The production of CT Iron involves several critical steps, each meticulously controlled to ensure quality:

- Smelting: Iron ore is melted in a blast furnace to produce molten iron.

- Pouring: The molten metal is poured into molds to create the desired shapes.

- Cooling and Solidification: The metal cools and solidifies, forming the final product.

Innovative techniques like cold extrusion, combined with high purity materials, enhance the precision and performance of CT Iron products. Manufacturers like Oban's CT Iron Series employ exacting specifications and tolerances to produce consistent, high-quality items.

Types of CT Iron

CT Iron encompasses various types, each tailored to specific applications:

Gray Cast Iron

Characterized by its graphite flakes, gray cast iron offers excellent wear resistance and damping properties, making it suitable for machine bases and engine blocks.

White Cast Iron

With its carbon combined into iron carbide (cementite), white cast iron exhibits extreme hardness but is brittle, limiting its use to specialized applications like grinding balls and teeth for crushing machinery.

Ductile Iron

Also known as nodular iron, this type features spherical graphite nodules, providing superior strength and ductility compared to traditional cast iron. It is widely used in automotive and industrial components.

Applications in Various Industries

CT Iron's versatility ensures its presence across numerous sectors:

- Construction: Used in structural components, railings, staircases, and gates.

- Automotive: Employed in engine blocks, brake discs, and other critical parts.

- Cookware: Its heat retention and distribution properties make it a favorite for skillets and Dutch ovens.

- Electrical: CTs (Current Transformers) rely on the core activity corresponding to CT equivalent circuits for accurate current measurement.

Advantages and Disadvantages

Advantages

- Excellent machinability.

- Lightweight yet strong.

- High wear resistance.

- Good damping characteristics.

Disadvantages

- Potential brittleness in certain types.

- Requires careful maintenance to prevent rust.

Maintenance and Care

While CT Iron is robust, proper maintenance ensures its longevity:

- Seasoning: For cookware, regular seasoning with oil prevents rust and enhances non-stick properties.

- Cleaning: Use mild soap and avoid harsh abrasives to preserve the surface.

- Storage: Keep items in dry environments to prevent moisture exposure.

With diligent care, CT Iron products can last for generations, maintaining their functionality and aesthetic appeal.

The Future of CT Iron

As technology advances, the role of CT Iron continues to evolve. Modern manufacturing techniques and material science innovations promise to enhance its performance and expand its applications. From sustainable building practices to cutting-edge automotive designs, CT Iron remains at the forefront of progress.

Moreover, the growing emphasis on recycling and environmental sustainability aligns with CT Iron's recyclable nature, ensuring its relevance in a rapidly changing world.

Conclusion

CT Iron represents a remarkable fusion of tradition and innovation, offering unparalleled strength, versatility, and reliability. By understanding its composition, manufacturing processes, and applications, we gain a deeper appreciation for its importance in shaping our world. Whether you're a homeowner, engineer, or chef, CT Iron provides solutions tailored to your needs.

We invite you to explore further, share your experiences, and contribute to the ongoing conversation about this remarkable material. Together, we can unlock the full potential of CT Iron and drive progress in countless fields.

For more insights, stay tuned to our blog and engage with our community. Your feedback and questions are invaluable as we continue to explore the fascinating world of metallurgy and beyond.

UR105 CT_Iron_TroisQuart | WATCHVIEWS

UR-105 CT IRON LIMITED TO 50 PIECES – URWERK SHOP

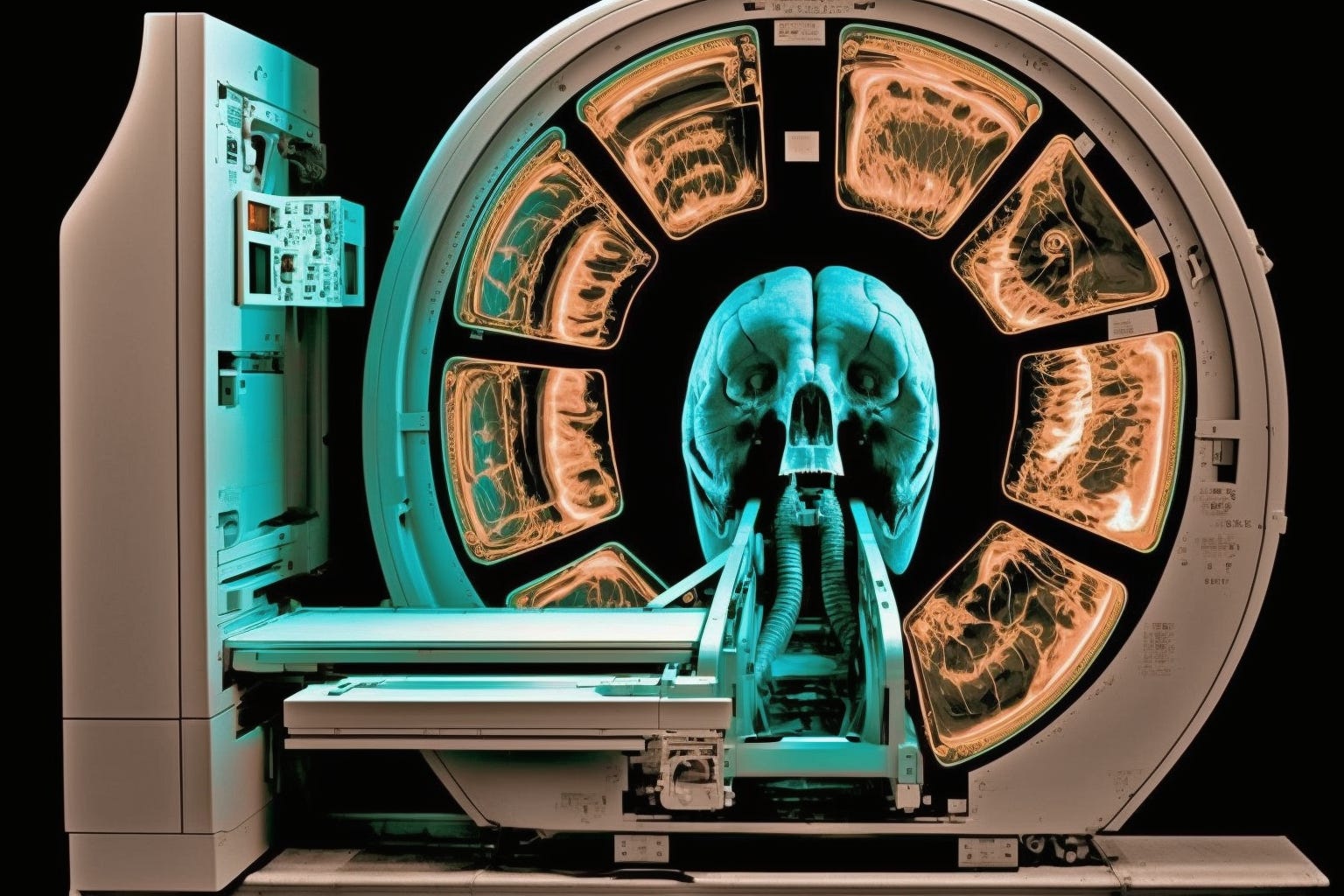

What is a CT Scan - by Hailey - Know It All